With Deacom ERP software, quality control checkpoints can span the entire product lifecycle, from formulation through shipment. QC tests are often incorporated into various business processes.

Raw materials are received on purchase orders

Finished goods are produced on production jobs

Previously sold products are returned

Process control in manufacturing requires that your warehouse management system, quality control testing, and document generation are all operating within the same platform.

With these types of functions native to the core ERP system, manufacturers have the opportunity to eliminate the risk of bypassing steps in their processes.

Learn more +

Avoid the possibility of having users bypass steps in your processes.

Ensure QC holds prevent products from being picked, consumed, or shipped.

Confirm products meet customer specifications.

Reduce the risk of liability and product recalls.

Assure that accurate and real-time QC test results are accessible to stakeholders.

“We are familiar with the value that Deacom has delivered to other similar food manufacturing businesses, so we have no doubt that Deacom is the best solution for us. Our team is truly excited about the impact Deacom will have on our production process and quality control.”

– Greg Johnson, President, Maple Island Inc.

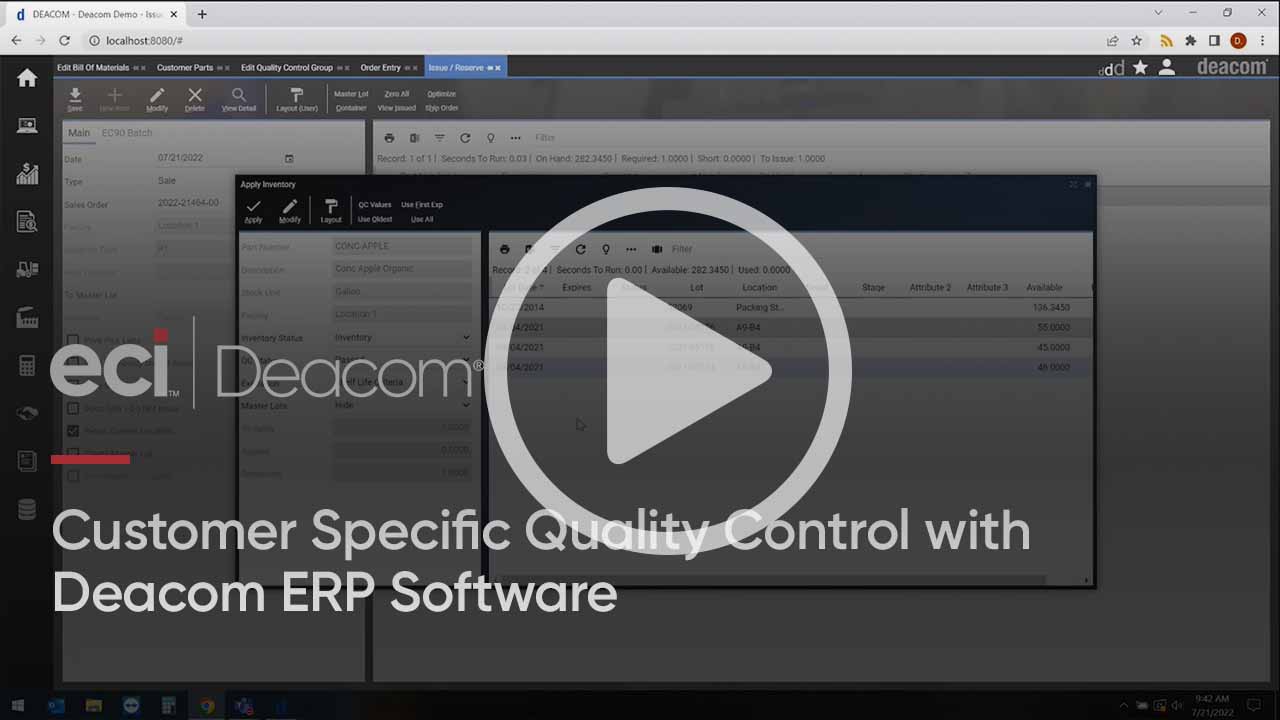

See Customer Specific Quality Control in Action

You need an effective means to ensure that the correct products are delivered to your clients, especially if they want precise quality control criteria. In this brief video, learn how to manage QC specs for the finished product, such as particular tests, goal values, and min/max values of acceptance, and have the warehouse picking process accurately identify which lots will fulfill those client needs.

Accomplish all of this and more with Deacom ERP

QC Management

Create and manage quality control tests, groups, and security.

Administrate QC Security

Assign QC groups to item masters and associate user groups with QC security groups.

QC Testing on Received Items

Manage tests performed when raw materials are received on purchase orders.

Configure Production Tests

Control the way tests are performed when materials are produced and finished on production jobs.

Allow Multiple Tests

Perform multiple QC passes and record those results.

Generate Reports

Monitor the status of QC testing with built-in reporting.

Unapprove QC Results

Unapprove QC results in production situations where material has not yet been finished and the production job is still open.

Allow Exceptions

Modify results on inventory reports and allow for marking items at-risk.

Regulatory Requirements

Configure specific QC tests to require an E-Signature for approval and results.

Explore more of Deacom ERP software

COA Documents

Automatically generate a CoA document with customer-specific QC specifications at the time of shipment.

Formulation

Adjust and scale formulas as needed knowing that all changes will automatically be reflected in inventory, production, and planning tools.

Production Management

Simplify the process of creating, scheduling, staging, and analyzing production jobs within the single ERP system.

Weigh Up

Use functionality within the ERP system to increase the efficiency and accuracy of your weigh up processes.