Reduce Complexities

With its native capabilities, Deacom Dairy ERP software eliminates the need for multiple legacy systems, modernizing your ERP solution while ensuring scalability for the dairy industry.

Focus on Customers

Improve your direct store delivery experience, manage multi-channel sales with built-in ecommerce features, and handle private label product development with Deacom's dairy ERP solutions tailored to specific customer requests.

Gain Real-time Visibility

Track hauler pickup schedules, monitor fluid pricing, manage production lot tracking, and access quality control information with ease. Deacom’s dairy ERP software provides real-time visibility across all facilities, ensuring smooth operations and compliance.

Whether you contract manufacture, co-pack, or produce your own dairy products, Deacom’s dairy ERP solutions support your complex production, quality control, warehousing, scheduling, regulatory reporting, and traceability needs within the dairy industry.

Track and trace batches of dairy products through the entire supply chain with our ERP for dairy industry professionals.

Monitor the raw material quality of dairy products and adjust recipes and planning accordingly using a dairy ERP solution.

Manage quality control processes, including cold chain values, to ensure minimum shelf life and regulatory compliance with Deacom’s dairy manufacturing software.

Seamlessly handle pricing, dairy information, private labels, and packaging through our ERP for the dairy industry.

Plan maintenance and repair schedules to integrate smoothly into production with Deacom’s dairy ERP software.

“Having used multiple ERP systems, I am so pleased with my experience with Deacom. Their "no bolt-on" approach allows the user to find all resources needed within the software without customization.”

Capterra User Review

“Users praise Deacom ERP for its robust functionality, particularly its 'tight process control.' This allows our business to establish repeatable and scalable practices, leading to greater efficiency and consistency.”

SelectHub User Review

“The Deacom team has been and is great to work with! They willingly make time for us as a customer and listen attentively to our needs. This has always resulted in collaboration and a true exchange of ideas. Not only are they willing to offer suggestions but they accept suggestions for improvement as well.”

GetApp User Review

“We went from a system that struggled to identify shortages for upcoming production runs. Deacom works great! The aspects that I personally appreciate are Inventory Management, Instant MRP, and Ticketing functionality. It was such a leap up from what we were using.”

G2 User Review

Download our brochure for more information on dairy ERP solutions

DownloadONE Dairy ERP Solution Purpose-Built for Your Industry

ONE Solution for Your Industry

The Deacom ERP platform is developed specifically to meet the unique needs of dairy producers.

ONE Predictable Price

Understanding that an ERP implementation is a significant investment, dairy manufacturers that implement Deacom have full pricing transparency going into the project.

ONE System

Deacom has the largest set of native dairy software capabilities that combines industry-specific functionalities and processes with functional depth within one system – on premise, managed cloud, or hybrid.

ONE User Experience

Intuitive and consistent working experience across all departments, all platforms, and all devices with Deacom ERP.

ONE Team

The Deacom team is the single partner for everything you need: software, implementation, training, service, and support.

Deacom ERP System Capabilities for Dairy Production

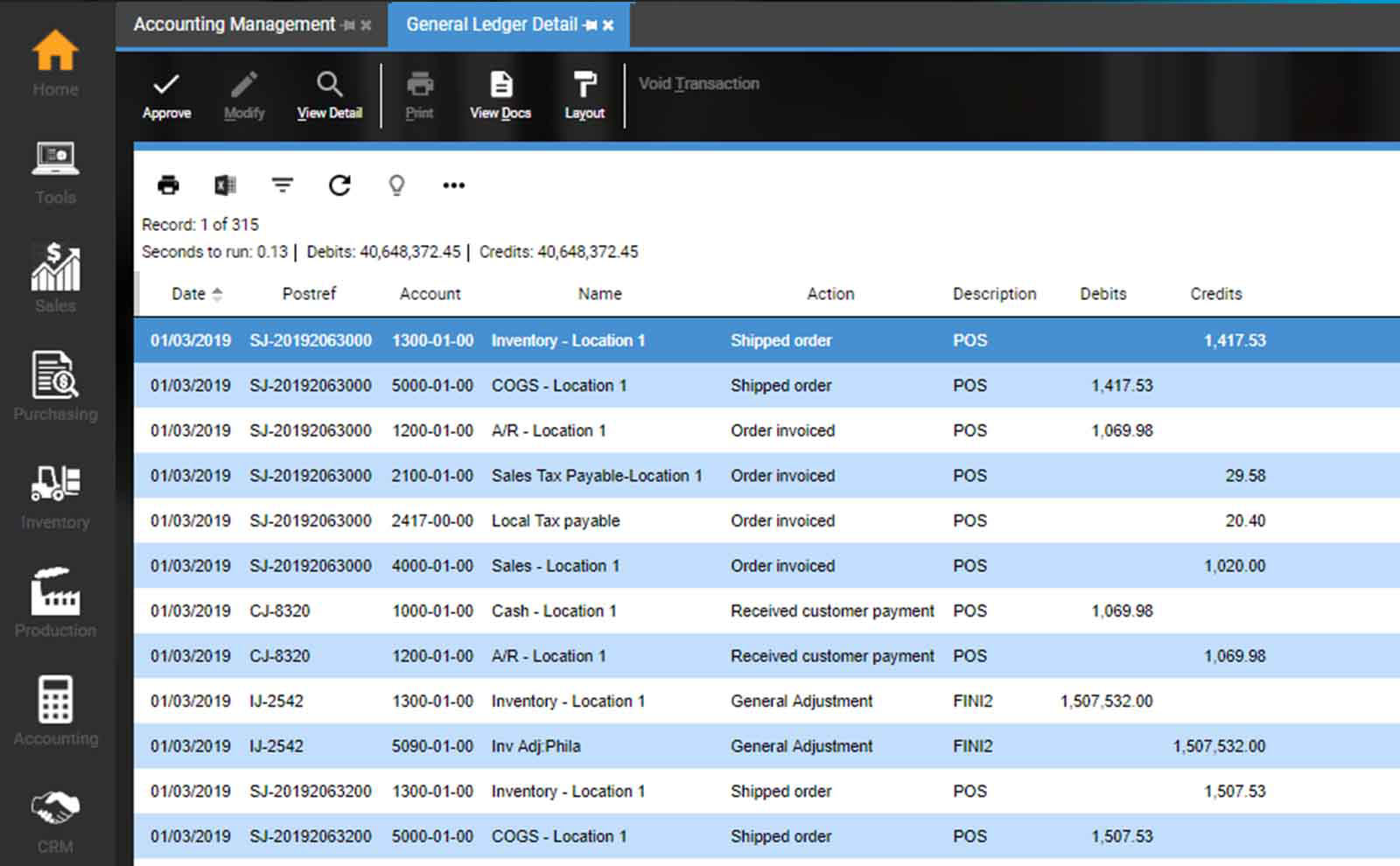

Accounting/Finance

Business Intelligence/Dashboards

Catch Weight

Customer Management (CRM)

Direct Store Delivery (DSD)

Document Generation

Document Storage

Ecommerce

Electronic Data Interchange (EDI)

Formulation/BOM

Inventory

Label Generation

Mobile Apps

Maintenance (MRO)

Material Requirements Planning (MRP)

Multi-Company/Facility

Point of Sale

Pre-Weigh

Production Routings

Production Data

Product Configurator

Purchasing

Quality Control/Quality Assurance

R&D/Project Management

Regulatory Management

Reporting

Sales

Scheduling

Serialization/Traceability

Warehousing/Scanning

Achieve more with Deacom Dairy ERP Software

Optimize production and purchasing based on seasonal demand with dairy manufacturing software.

Streamline production schedule changes efficiently using our dairy ERP solutions.

Centralize supply and demand data through material requirements planning with ERP for the dairy industry.

Use the warehouse management system to receive, scan, and track raw materials seamlessly.

Record direct store delivery transactions, track inventory levels, record returns, and handle all order and cash reconciliation electronically.

Enforce FEFO (First Expired, First Out) inventory management rules to reduce unnecessary waste.

Automate quality control release processes and prevent warehouse staff from handling lots on QC hold with our dairy ERP solutions.

Facilitate intercompany inventory transfers with ease using Deacom’s ERP software for dairy manufacturing.

Explore some of the other industries we serve

Candy & Snack

Create strict lot control with the WMS, streamline your ability to transact and report in a multi-facility environment, and improve sales order picking efficiency through zone and wave pick options.

Food & Beverage

Support inbound and outbound EDI transactions, formulate and generate nutritional fact panels, and use the lot tracking implosion/explosion reports in the event of a recall.

Meat

Manage the complexities of receiving and producing catch weight items, maintain product shelf life rules for customers and products with varying requirements, and connect your production equipment to an auto-finishing application to improve production efficiency.

Private Label Manufacturing

Access centralized data for real-time decision making, forecast production capacity requirements, and ensure customer specific quality standards are met.