Industries Served

Adhesives & Sealants

Cannabis

Chemical

Cosmetics & Personal Care

Distribution

Food & Beverage

High-Tech

Medical Device

Nutraceutical

Oil & Gas

Paint, Ink, & Coatings

Pharmaceutical

Challenges with Process Control

Hyper-Tight Process Control™, a unique component of Deacom ERP software, is what manufacturers need to reduce the cost of being wrong. This includes the negative implications that can result from legal claims, recalls, low customer satisfaction, removal from preferred supplier lists, and much more. The costs can range from a few thousand to billions of dollars, not to mention the tarnished reputation.

Eliminate the cost of being wrong with Hyper-Tight Process Control™

- One system for planning, receiving, production, warehousing, shipping, process, and quality control

- Integrated quality control procedures and measures

- Configurable quality checkpoints

- Checkpoints that cannot be bypassed

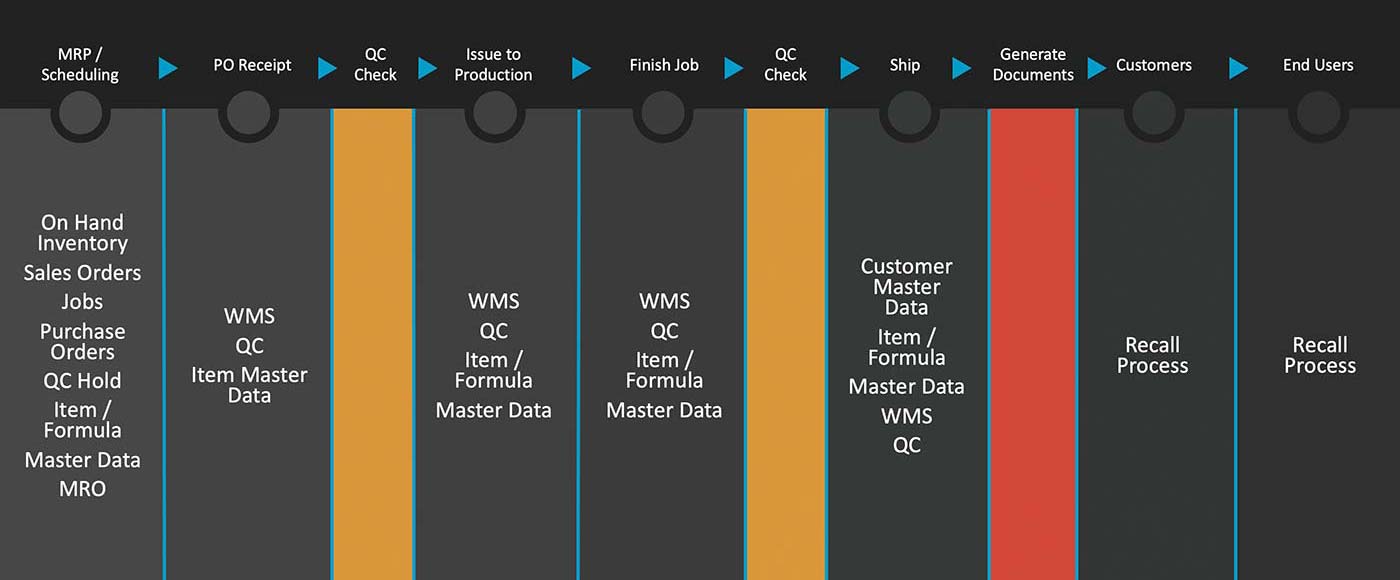

Hyper-Tight Process Control™ – Control Elements

Formulation

Describe how an item is made, what goes into it, what the physical properties are, and what quality control requirements must be fulfilled.

MRP / Scheduling

Calculate what needs to be bought or produced to have the materials on hand in the proper time to go through the manufacturing process.

Purchase Order Receipt

Driven by the MRP process, when a purchase order arrives, the first process checkpoint is active for the individual items that are in receiving.

Quality Control

Enforce quality control holds where the quality specifications are checked.

Production

Materials issues to production are approved by the previous quality control checkpoint and transactions typically done with the warehouse management system scanners.

Job Finishing

When production has finished, another process checkpoint initiated by Hyper-Tight Process Control™ checks that the finished quantity has consumed adequate raw or intermediate materials or products.

Shipping

By using modern barcode scanning practices, you can ensure the warehouse team does not ship lots that are on QC hold to customers.

Document Generation

Generating required documents, such as a bill of lading, COA documents, or packing lists, are all dependant on the previous process checkpoints as part of the Hyper-Tight Process Control™ functionality within the ERP system.

Hyper-Tight Process Control™ – Benefits

Hyper-Tight Process Control™ vs. Process Control

| Hyper-Tight Process Control™ | Process Control | |

|---|---|---|

| All functionality in one ERP system – Planning, receiving, quality control, warehousing, production, job finishing, shipping and document generation | Yes | Bolt-Ons |

| Checkpoints definable | Configurable | Custom Programming |

| Thresholds based on formulas | Configurable | Programming |

| Subsequent process stops take previous stops into consideration | Configurable | Custom Programming |

| Real-Time Execution | Yes | Based on Integration |

| Process Administration | Yes, native to the system | Custom Programming |

Challenges with Business Complexity

To be successful in this complex and fast-changing world, companies must be highly agile and flexible; able to identify opportunities and make informed decisions quickly in order to exploit those opportunities.

Reducing complexity in their business processes with an ERP system that is easier to implement and manage, that its users love and that provides a single source of information and truth, is key to accomplishing this.

Complexity Made Simpler by...

ONE Solution for Your Industry

The Deacom ERP platform is developed specifically to meet the unique and often complex needs of process manufacturers.

ONE Predictable Price

Understanding that an ERP implementation is a significant investment, businesses that implement Deacom have full pricing transparency going into the project.

ONE System

Deacom has the largest set of native software capabilities that combines industry-specific functionalities and processes with functional depth within one system – on premise, managed cloud, or hybrid.

ONE User Experience

With a single login, user have an intuitive and consistent working experience across all departments, all platforms, and all devices with Deacom ERP.

ONE Team

The Deacom team is the single partner for everything you need: software, implementation, training, service, and support.

Benefits of our Complexity Made Simpler Approach

ONE System

- Faster implementations – no integration work

- Easier to upgrades – all functionality included in one system

- Lower cost to run the system – lower total cost of ownership because of less integration work

One User Experience

- Lower training cost/time – a common UI and management of data and processes

- Increased flexibilities / efficiencies – users can easily perform jobs outside their core responsibilities

- Higher employee satisfaction – empower users with a solution they can actually use

ONE Team

- No disputes on responsibilities – all services from a single partner

- Faster resolutions – no need for collaboration and solution discussions

- Best advice – a partner who covers the full solution lifecycle

ONE Predictable Price

- Predictable Investment – no hidden fees for extra software, third-party integrations, or release management

- Transparent decision making – no hidden agendas or costs

- What you bought is what you get – upfront clarity on deliverables for your investment

What our customers are saying...

– Jeff Van Drunen, President of FutureCeuticals

“We’ve been able to dramatically simplify management of the daily business, the speed in which we close our books, and the way in which we report out on our performance – all those things have been significant steps in the right direction since implementing Deacom.”

– Chris Kiser, CEO of Teasdale Foods